PROJECTS

ION THRUSTER

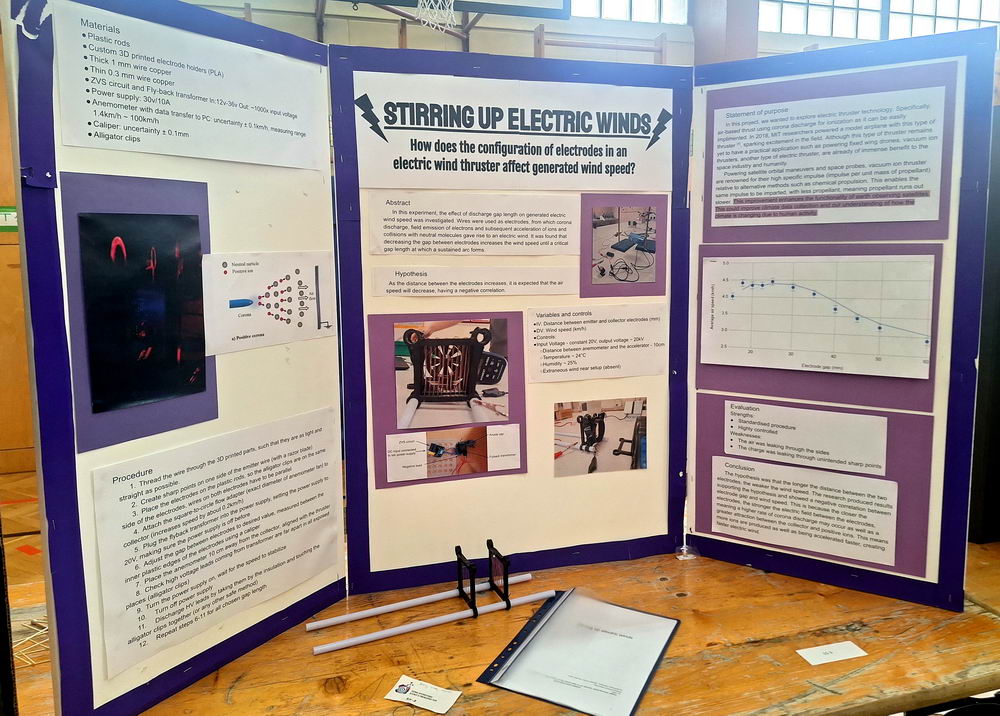

This project won Vienna Science Fair 2024

DESKTOP WIND TUNNEL

7-foot plywood wind tunnel for airfoil experiments.

3D-PRINTED BLDC MOTOR

Proof that a brushless motor can be built with common tools.

RC PLANE

Foam block → framed fuselage; Arduino + nRF24L01 flight computer.

MODEL ROCKETS + LAUNCHRAMP

Rocket club

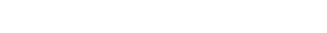

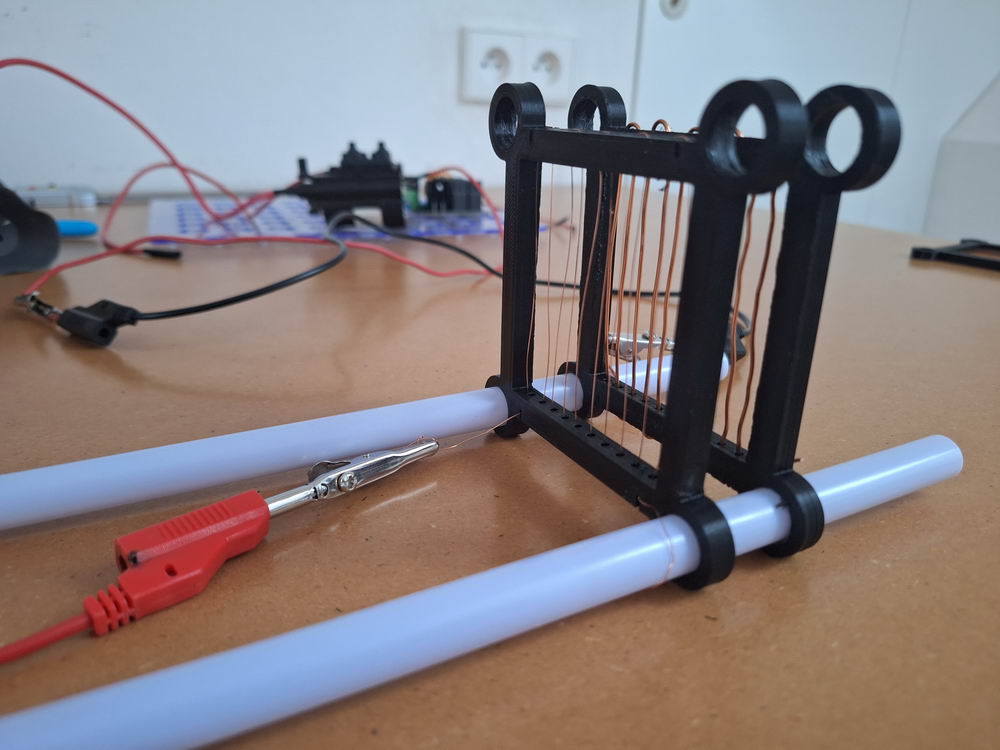

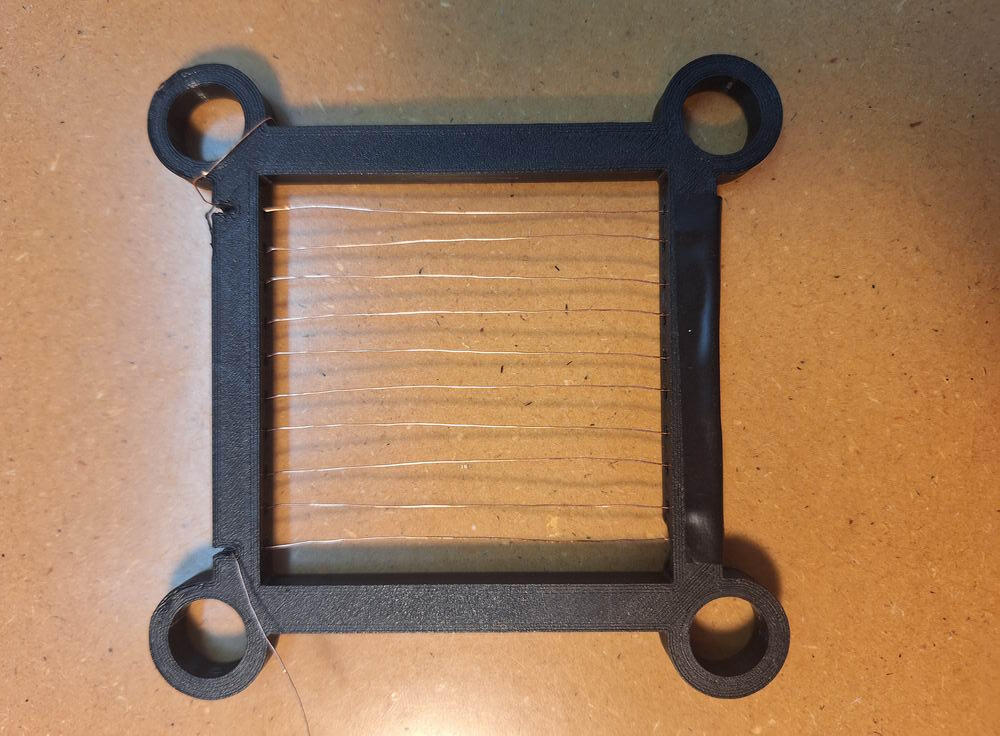

ION THRUSTER

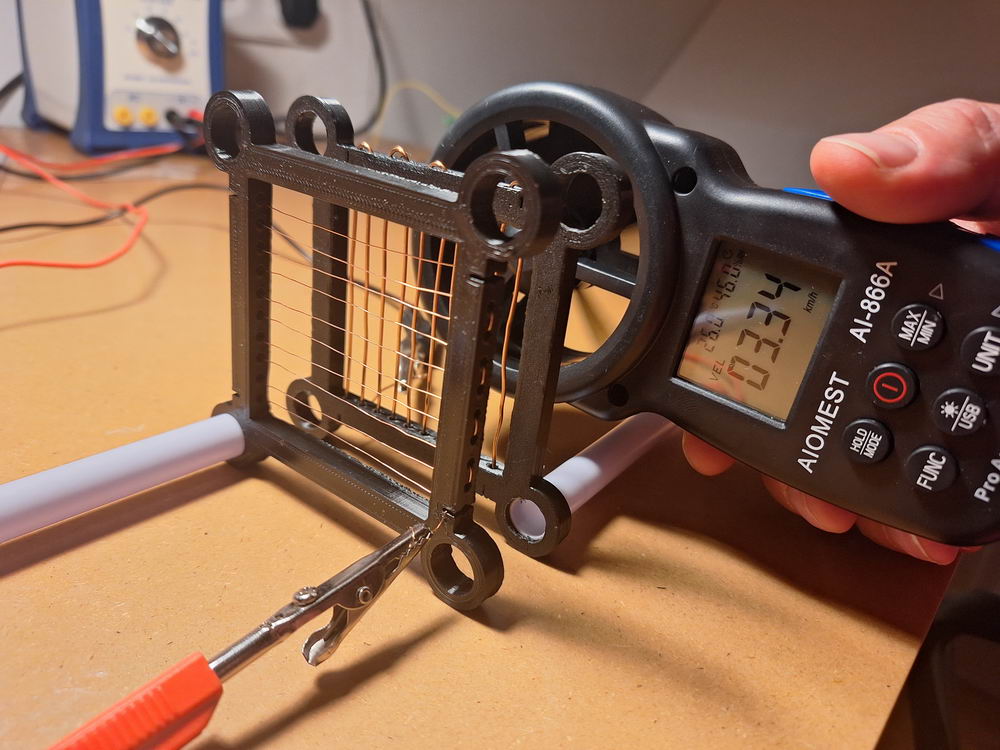

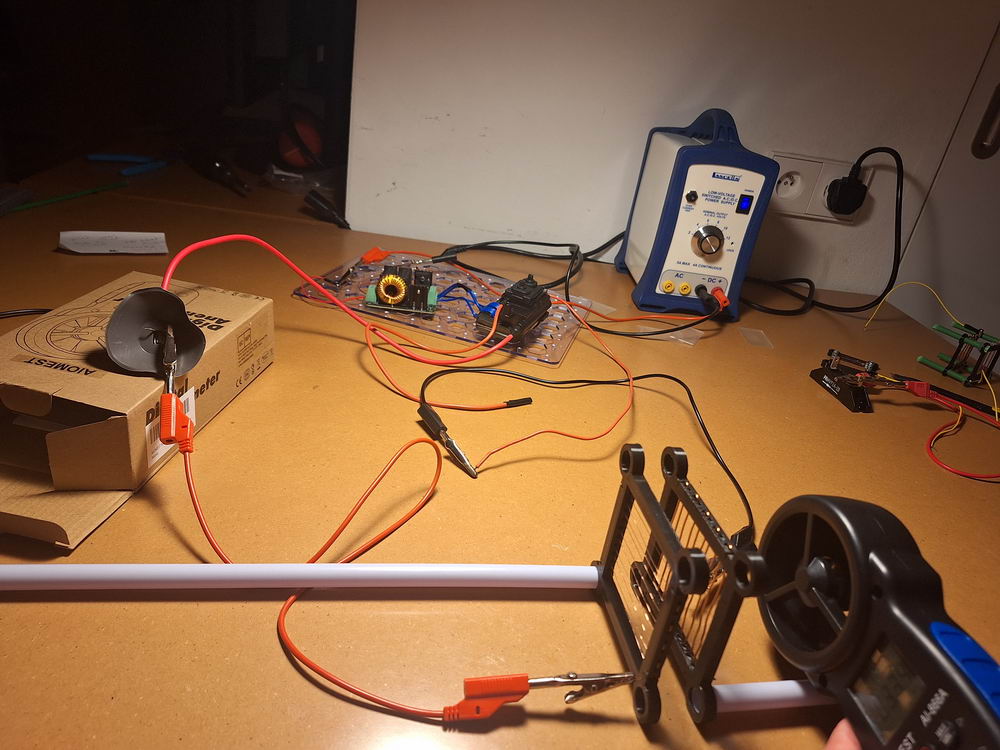

How does the configuration of the electrodes in an electric wind thruster affect generated wind speed?

In this experiment, the effect of discharge gap length on generated electric wind speed was investigated. Wires were used as electrodes, from which corona discharge, field emission of electrons and subsequent acceleration of ions and collisions with neutral molecules gave rise to an electric wind. It was found that decreasing the gap between electrodes increases the wind speed until a critical gap length at which a sustained arc forms.

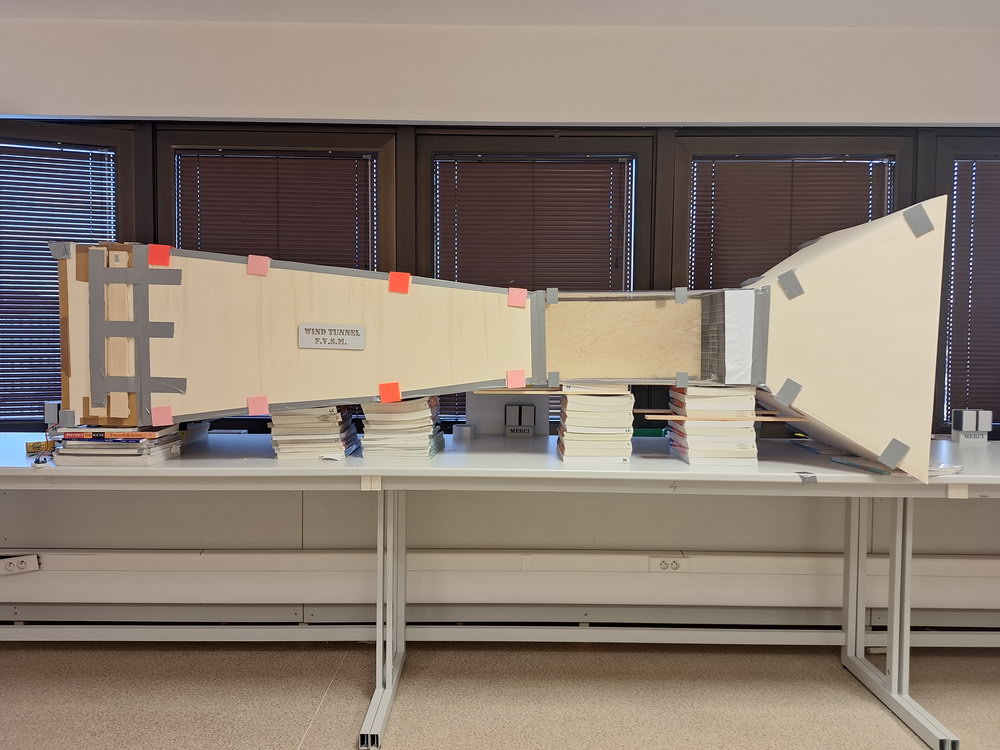

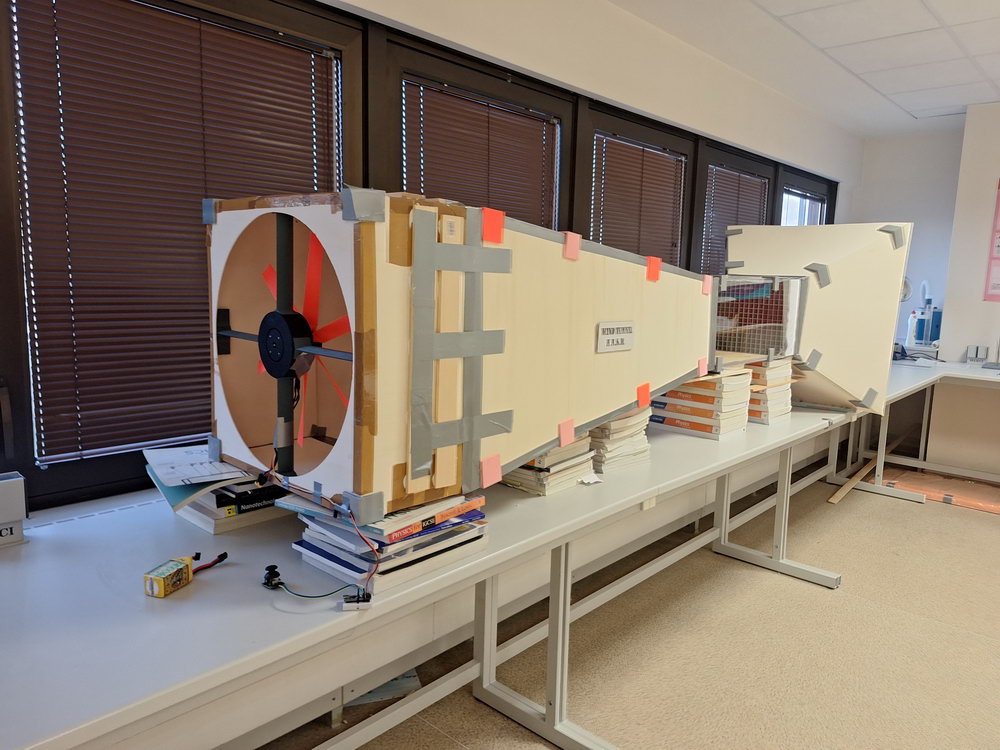

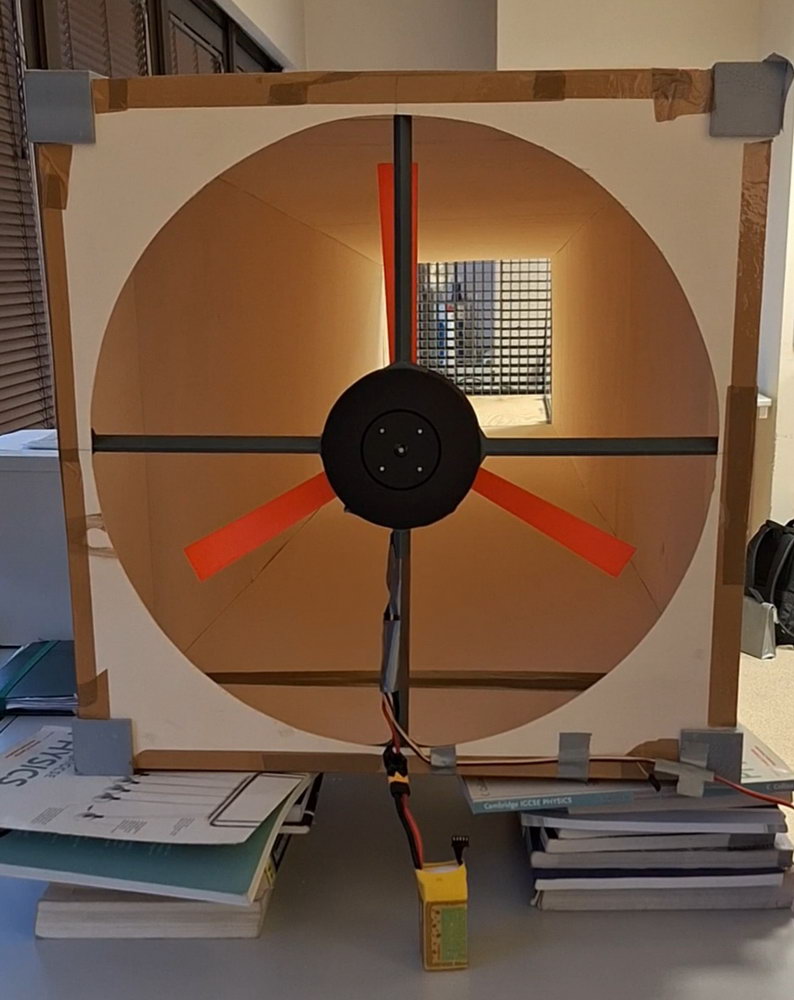

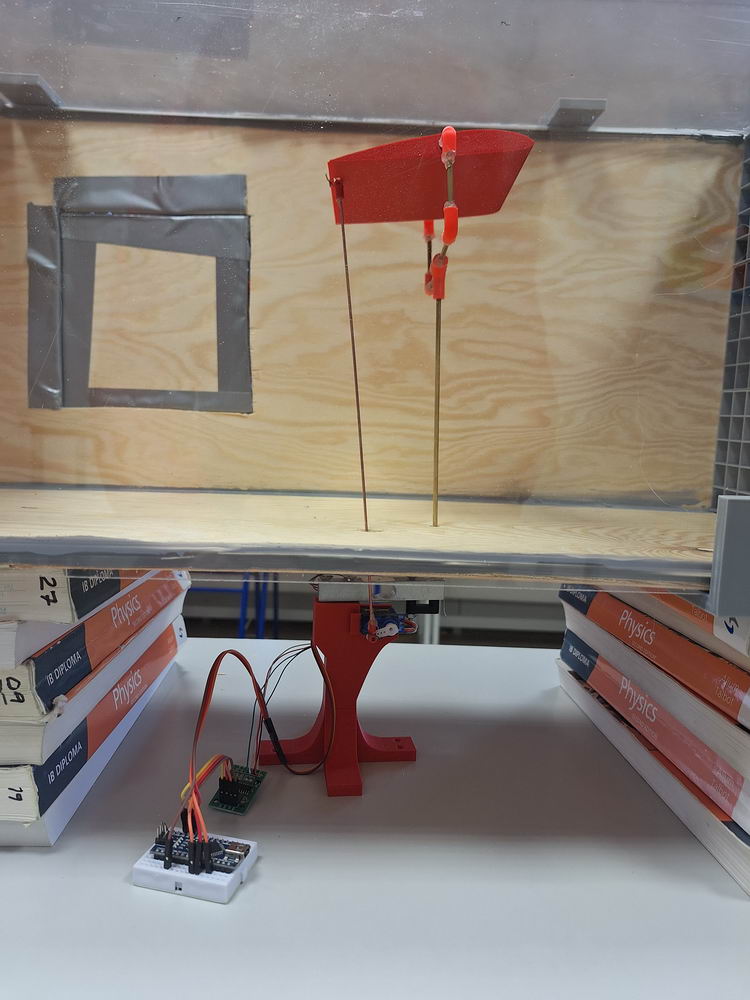

DESKTOP WIND TUNNEL

We built the 7-foot plywood wind tunnel for airfoil experiments.

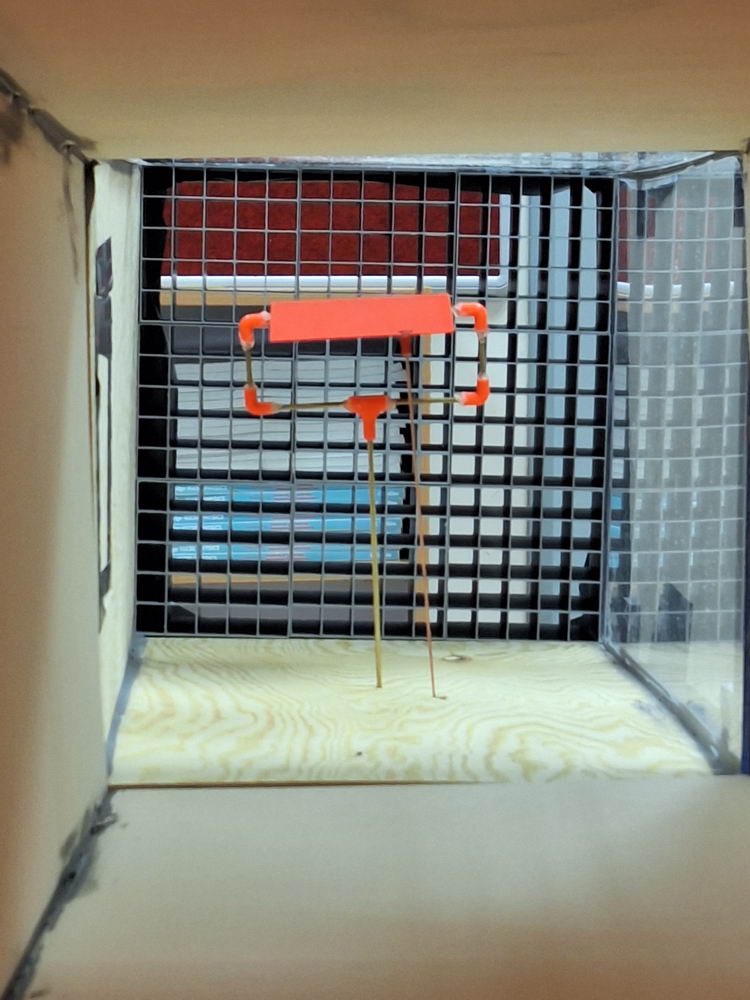

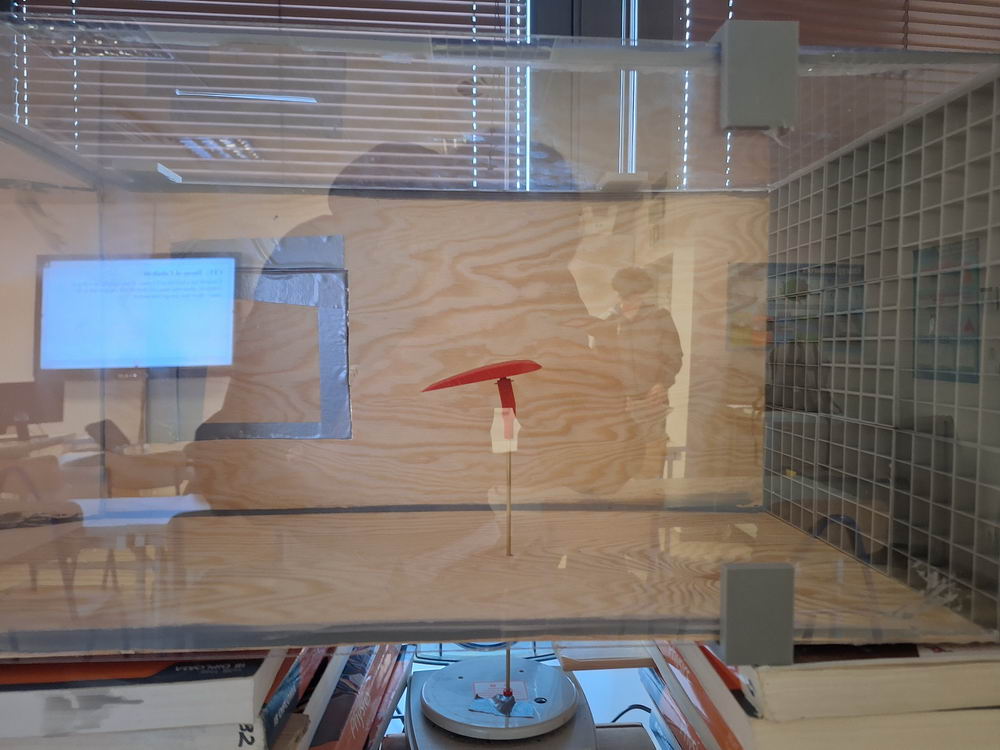

The geometry reflects the desire to accelerate the air to higher speeds in the test section to simulate more realistic airspeeds. The fan was designed using a BLDC motor with three blades with an adjustable rotation speed. We initially used 6 blades, but their excessive moment of inertia resulted in motor overcurrent and melted the enamel insulation on the winding wires, shorting the coil. To straighten the flow, which would otherwise resemble a helix, we printed an elongated mesh and tested its effectiveness using a matrix of strings.

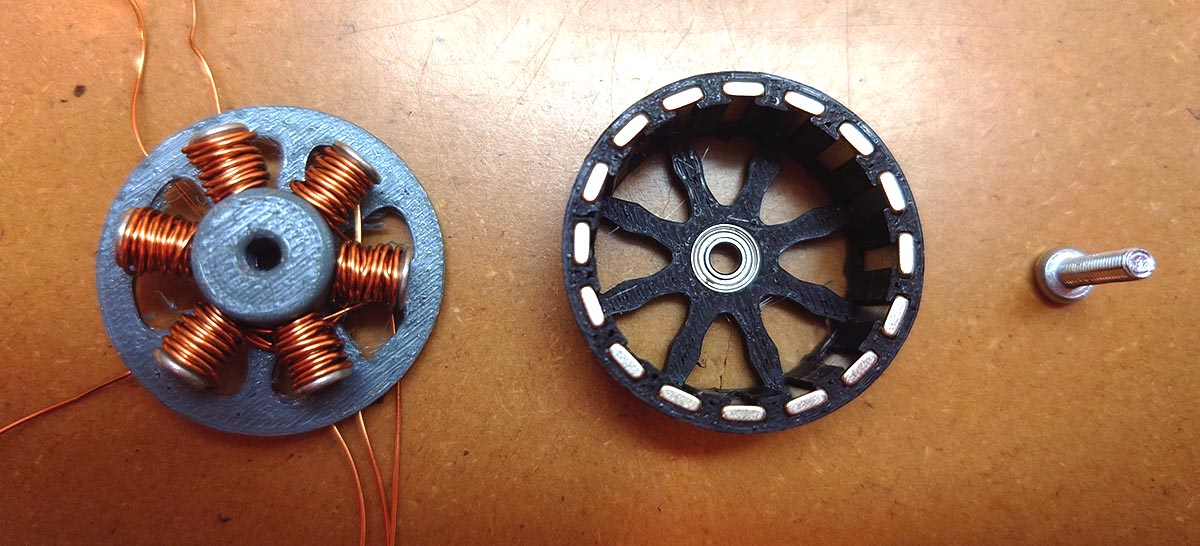

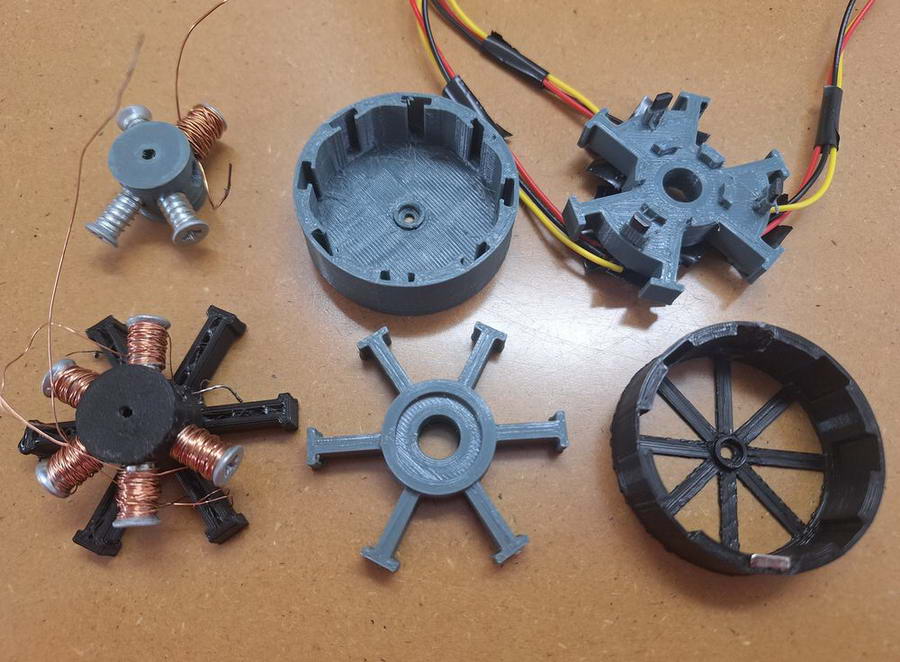

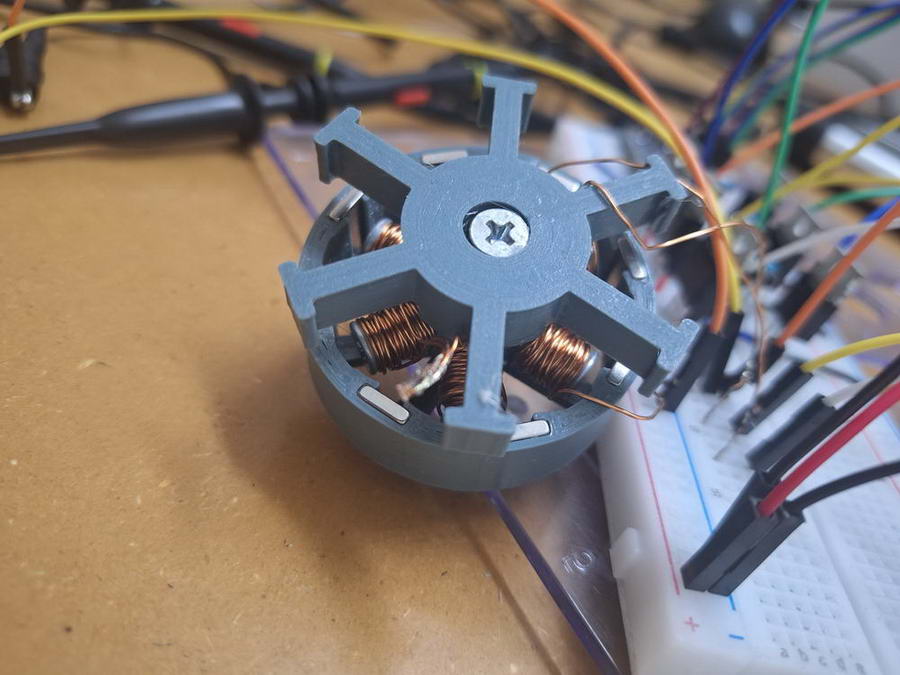

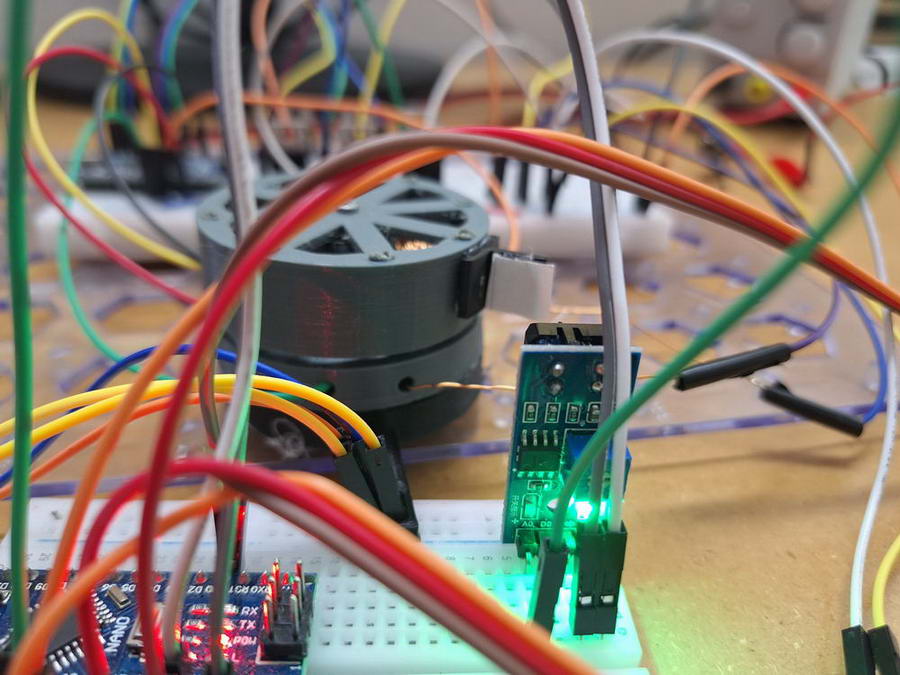

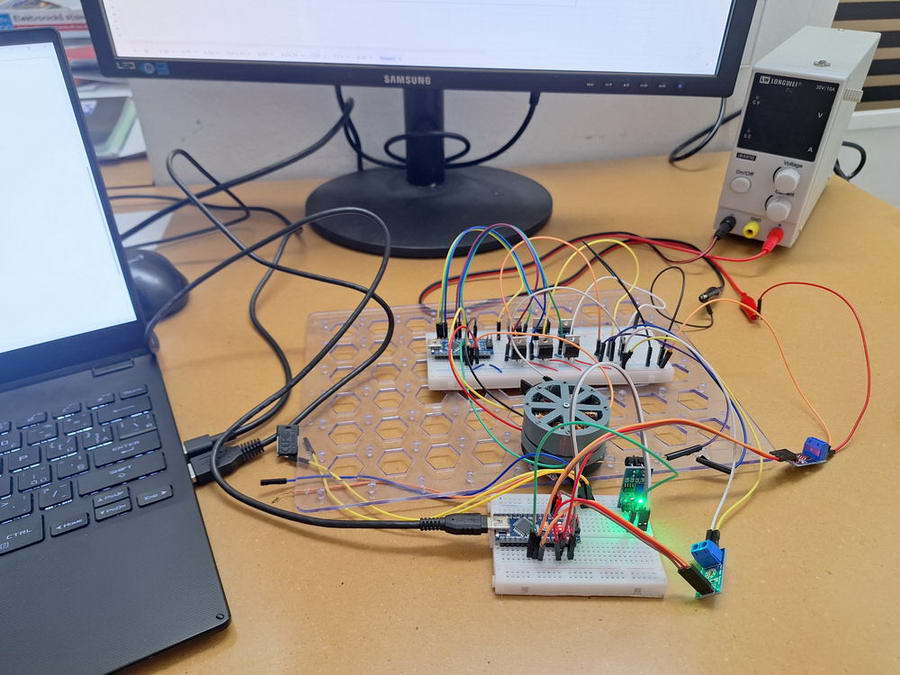

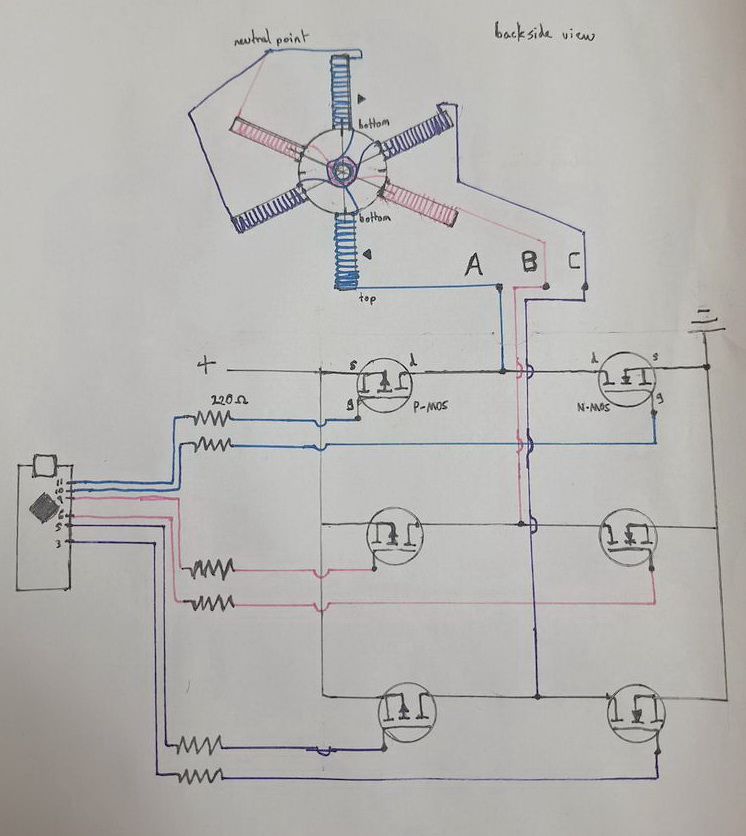

3D-PRINTED BLDC MOTOR

This DIY brushless DC motor was conceived as proof that a brushless motor can be built using readily available materials and tools. As such, I opted for a 3D-printed design using neodymium magnets, enameled copper wire, machine screws as the steel cores of the solenoids, and a ball bearing. Commutation was achieved using a simple circuit using an Arduino Nano, 3 MOSFET half-bridges, and 3 Hall-effect sensors. The Arduino takes the derivative of the magnetic flux from the sensors and determines what position the rotor is relative to the stator. It then outputs a high or low VGS to the MOSFETs to induce a magnetic field oriented in the direction that simultaneously attracts the approaching magnet and repels the outgoing magnet relative to that solenoid.

[BLDC, outrunner, 3-phase, unlaminated core, 3:4 coil to magnet ratio]

Issues: Eddy currents in the solid steel solenoid cores heat them up sufficiently to slightly deforme the PETG stator. Fix: use filament with a higher glass transition temperature or use laminated core which would inevitably eliminate the need for a 3D-printed stator anyways. Another improvement would be a designed optimized for air flow through the coils which this design didn’t have.

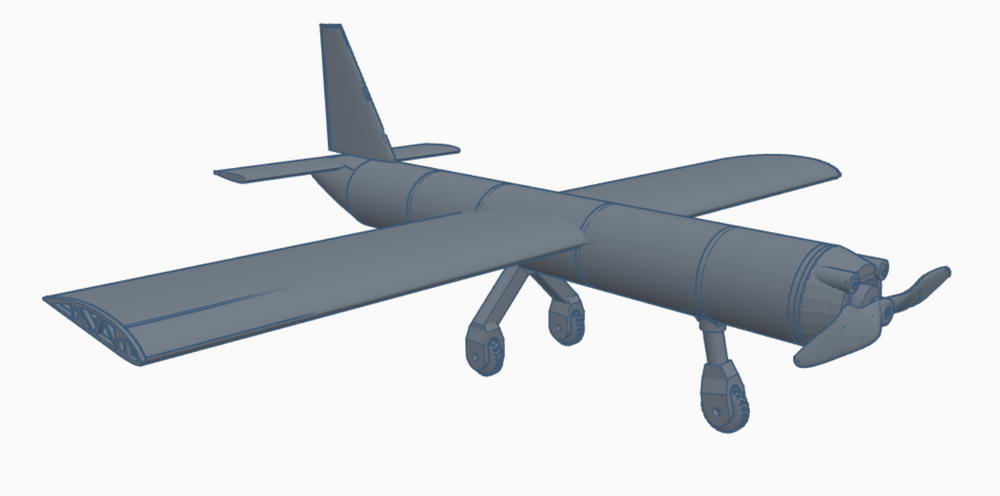

RC PLANE

What started as a flying foam block evolved into a framed fuselage. The flight computer was an arduino nano using an nRF24L01 transceiver module. The control surfaces were actuated with micro9G servos. The test flights demonstrated that the wings generated lift but ineffective control surfaces proved the plane directionally uncontrollable. The newer model crashed because the motor throttle failed because of a transmission issue, code issue or wire disconnection issue.

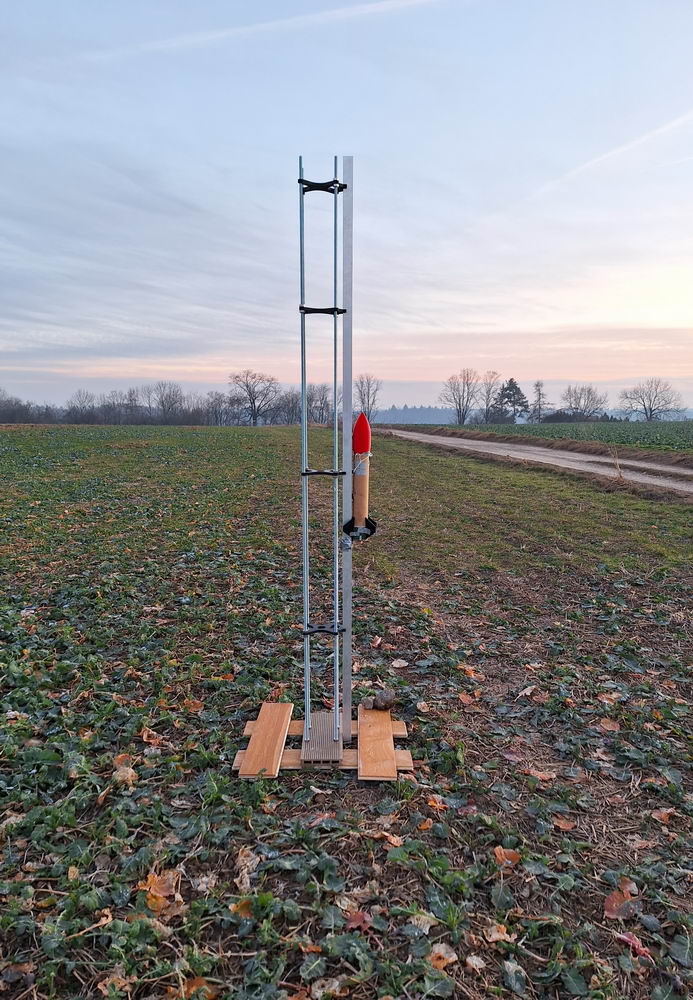

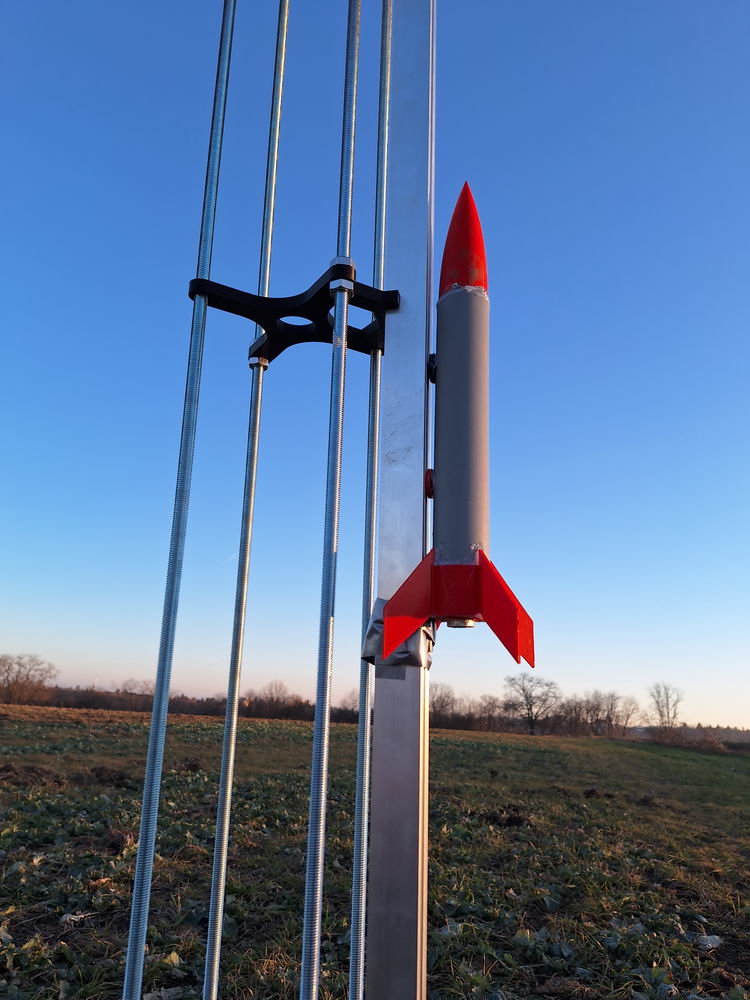

MODEL ROCKETS + LAUNCHPAD

Rockets?

Rockets rockets rockets !!!

CONTACT